Observations from an Engine Monitor Readout

Sape Mullender

February 2008

The EDM 700

Our Skylane has a JP Instruments EDM 700 Engine Monitor. It looks like this:

It displays Exhaust Gas Temperatures (EGT) and Cylinder Head Temperatures (CHT) for each of the six cylinders, as well as a few other parameters (such as bus voltage). It also stores these parameters in memory for after-flight analysis. I read this memory last week to see what typical flights look like. Before reading on, you may want to consult what I wrote about engine operations. I put it here.

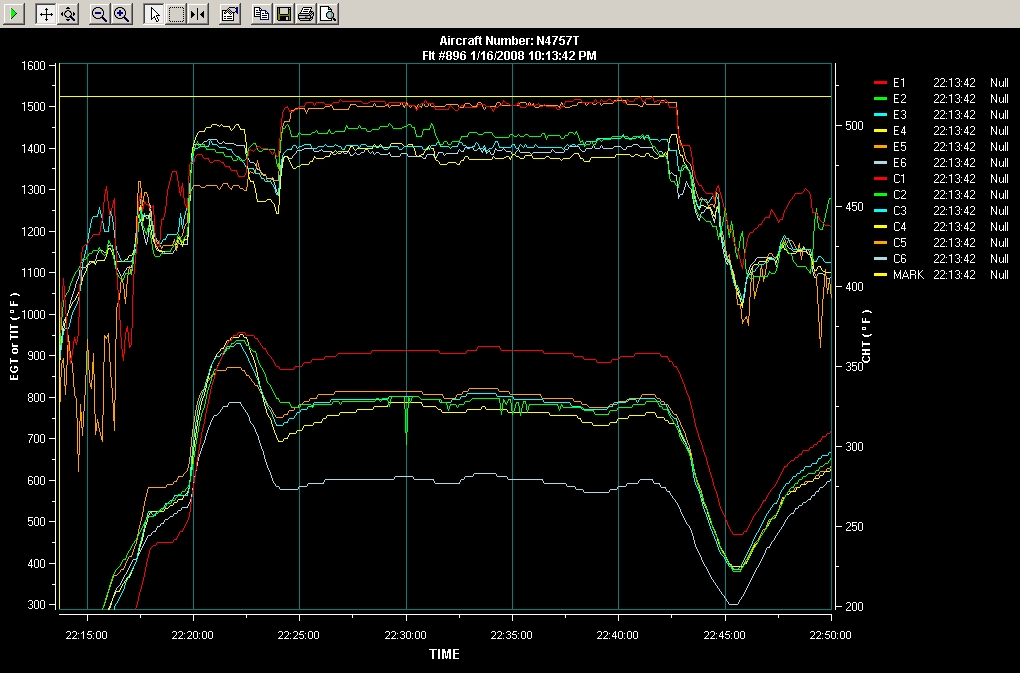

Let’s look at a typical graph.

The top six lines in the graph are exhaust-gas temperatures (EGT, scale on the left) and the bottom six lines show cylinder-head temperatures (CHT, scale on the right). The engine was started at 22:18 or so (the clock was off, so these times aren’t real). You can see the EGTs going to 1000°F or so while the CHTs remain below the scale. That makes sense: cylinders contain a lot of metal so they take time to warm up. This is visible everywhere in the graphs, CHTs lag well behind EGTs.

The engine run-up must have occurred at 22:18 or so, as witnessed by a small peak in EGTs. CHTs can be seen to catch up just a bit faster due to the run up — maybe.

Take-off happened at 22:20 and here things get interesting. EGTs rise to 1400°F. The CHT follows and climbs to 330°F. Cylinder 1 runs hottest and gets to 345°F. It’s a good idea to have those cowl flaps open to give the extra cooling so useful during this phase of flight.

Then all the temperatures go down. What’s happening?

We’re leveling off and reducing power. Leveling off means airspeed, and thus cooling, increases, so the CHT goes down. Reducing power means there’s less air/fuel to burn, so the EGT goes down too. That all makes sense.

But then EGT goes up again, even higher than during climb out. What’s happening here? The cowl flaps may have been closed, but that wouldn’t cause exhaust gases to get hotter. The effect is caused by the engine being leaned: The fuel-air mixture becomes optimal and there’s no longer any excess fuel to provide extra cooling. As a result, EGT goes up significantly, but, surprisingly, CHT stays almost put. How come?

The gases are much hotter due to the leaned mixture, but there’s also less of it. We’re no longer at full power, so the amount of fuel we burn per unit of time is less. This means that, although the gases are hotter, there’s compensation because of the reduced amount. So the CHT hardly goes up.

During the descent, the engine almost runs at idle, so temperatures rapidly come down. There’s lots of cooling because the airplane flies fast during descent. CHTs go way down. After landing, there’s suddenly hardly any cooling anymore and heat from the hot engine block warms up the cylinders again (remember that the cylinders have cooling fins on them, while the engine block does not; the latter also has greater mass, so its temperature doesn’t change all that fast.

The engine is shut down at 22:50 and the CHT is still increasing.

Here you see illustrated why you really should open the cowl flaps during taxi.

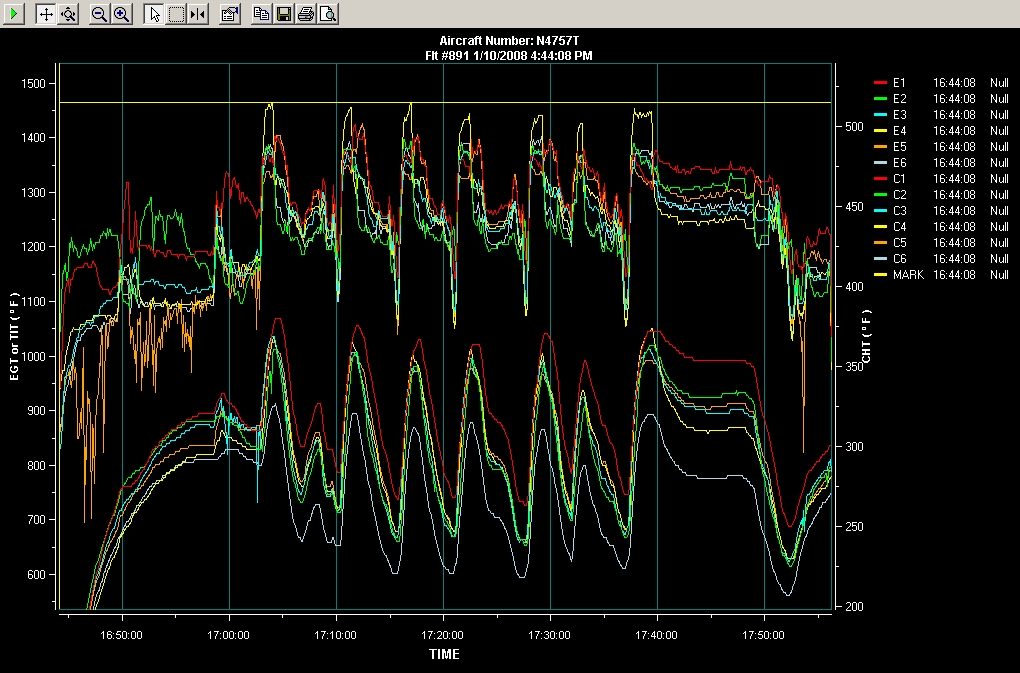

Now, just for the fun of it, let’s look at another graph from some time in January:

Here we have the typical scenario for pattern work. Repeated bursts of full power, followed by periods of idle power. Again, the CHT always lags behind the EGT. CHT stays nicely below 380 degrees or so.

During winter, CHT usually stays well below 400°F, but in the heat of the summer, you’ve got to pay attention to the cylinder head temperature. It can easily exceed 400°F or even 430°F during climbout. The air temperature, after all, is easily 50°F higher. There are two easy ways to deal with rising CHT: one is reducing power; the other is shallowing the climb in order to increase airspeed.

At full power, our engine runs extra rich for extra cooling. When power is reduced, this enriching effect goes away and, therefore, reducing power too little, may have an adverse effect. Shallowing the climb usually works better. Airspeed increases quickly and this tends to cool the cylinders very effectively.

Remember that running the engine too hot is very damaging. The metal starts to soften when its temperature gets above 400°F. 450°F is red-line for our engine. Serious damage will occur if temperatures get above that. I aim for CHTs no higher than 380°F which gives me a safety margin in case I’m not paying attention for a minute.